Anti-Oxidation PCB

Hoshineo Lcd-Tech is a high-precision and high-reliability electronic product solution provider focusing on "multi-variety, small batch, fast delivery". Provide a set of PCB design, Anti-Oxidation PCB, PCB production, electronic component procurement, PCBA samples, batch patch assembly as one of the one-stop service.

Send Inquiry

Anti-Oxidation PCB produced by Hoshineo Lcd-Tech refers to a printed circuit board (PCB) that has been specially treated to prevent oxidation of its surface copper layer during manufacturing, storage and use. This treatment can maintain the solderability and electrical performance of the PCB, while effectively improving product quality and extending service life.

Hoshineo Lcd-Tech China Anti-Oxidation PCB product parameters:

|

ltem |

Advanced |

|

|

Layer Count |

Max layer Count |

48L |

|

Board Thickness |

Max PCB Thickness |

6.45mm |

|

Min PCB Thickness |

0.1mm |

|

|

Finished Size |

Max Finished Size |

24.5*47inch |

|

Max Base copper Weight |

Iinner |

12oz |

|

Outer |

12oz |

|

|

Min Trace/spacing |

Iinner |

50/50um |

|

Outer |

45/45um |

|

|

Drilling Size |

Min Mechanical Drilling |

6mil |

|

Miin Mechanical Via Pad |

Iinner |

0.40mm |

|

Outer |

0.35mm |

|

|

Min BGA Pitch |

Min BGA Pitch |

0.35mm |

|

PCB Aspect Ratio |

Max PCB Aspect Ratio |

20:1 |

|

Solder Mask Dam |

Min Solder Mask Dam |

2.5mil |

|

Core Thickness |

Min Core Thickness |

0.05mm |

|

Bow & Twist |

Min Bow & Twist |

0.50% |

|

lmpedance Tolerance |

Min lmpedance Tolerance |

±8% |

Hoshineo Lcd-Tech China Anti-Oxidation PCB Feature

Surface protection: The remarkable feature of the Anti-Oxidation PCB is that its surface is specially treated to form a protective film, which can effectively isolate oxygen and moisture in the air and prevent the oxidation of the copper layer.

Excellent weldability: The anti-oxidation treatment ensures that the PCB surface remains good weldability during long storage and multiple welding processes.

Strong environmental adaptability: Anti-Oxidation PCB can adapt to different environmental conditions, including wet, high temperature, high humidity and other harsh environments.

Long-term stability: Anti-oxidation treatment can extend the service life of the PCB and reduce the failure and maintenance costs caused by oxidation.

Hoshineo Lcd-Tech China Anti-Oxidation PCB Application

Smartphones and tablets: Anti-Oxidation PCB in these devices need to withstand multiple insertions and welds in daily use, and antioxidant treatment ensures that the solderability and electrical performance of Anti-Oxidation PCBs remain stable over a long period of time.

Wearable devices: such as smart watches, health monitors, etc., due to their small size and need to be worn for a long time, the antioxidant performance ofAnti-Oxidation PCB has high requirements.

Automation equipment: In industrial automation control systems, Anti-Oxidation PCBs are often in the environment of high humidity, high temperature or corrosive gases, and anti-oxidation treatment can effectively prevent oxidation of the copper layer to ensure the stable operation of the equipment.

Industrial robots: Anti-Oxidation PCBs are widely used in robot joints, sensors and other parts, and antioxidant treatment can extend the service life of these parts and improve the overall reliability of the robot.

On-board electronic equipment: such as navigation, car audio, reversing radar, etc., these devices need to withstand various vibration and temperature changes during the car driving, and Anti-Oxidation PCB can ensure that these devices work properly in harsh environments.

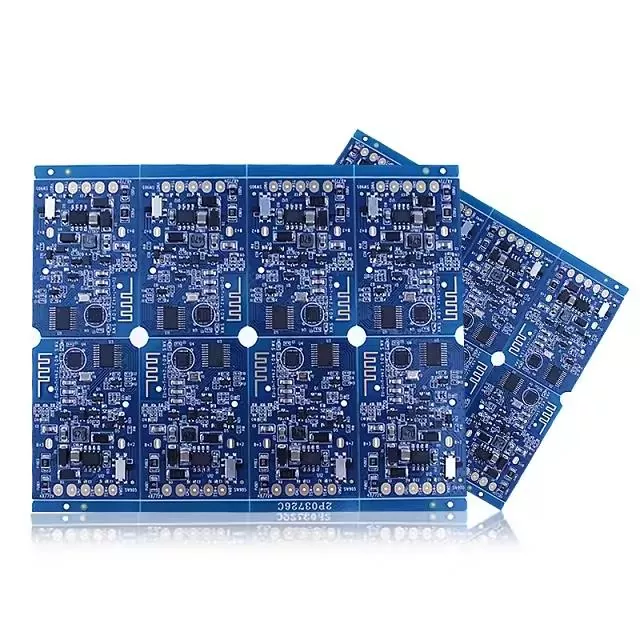

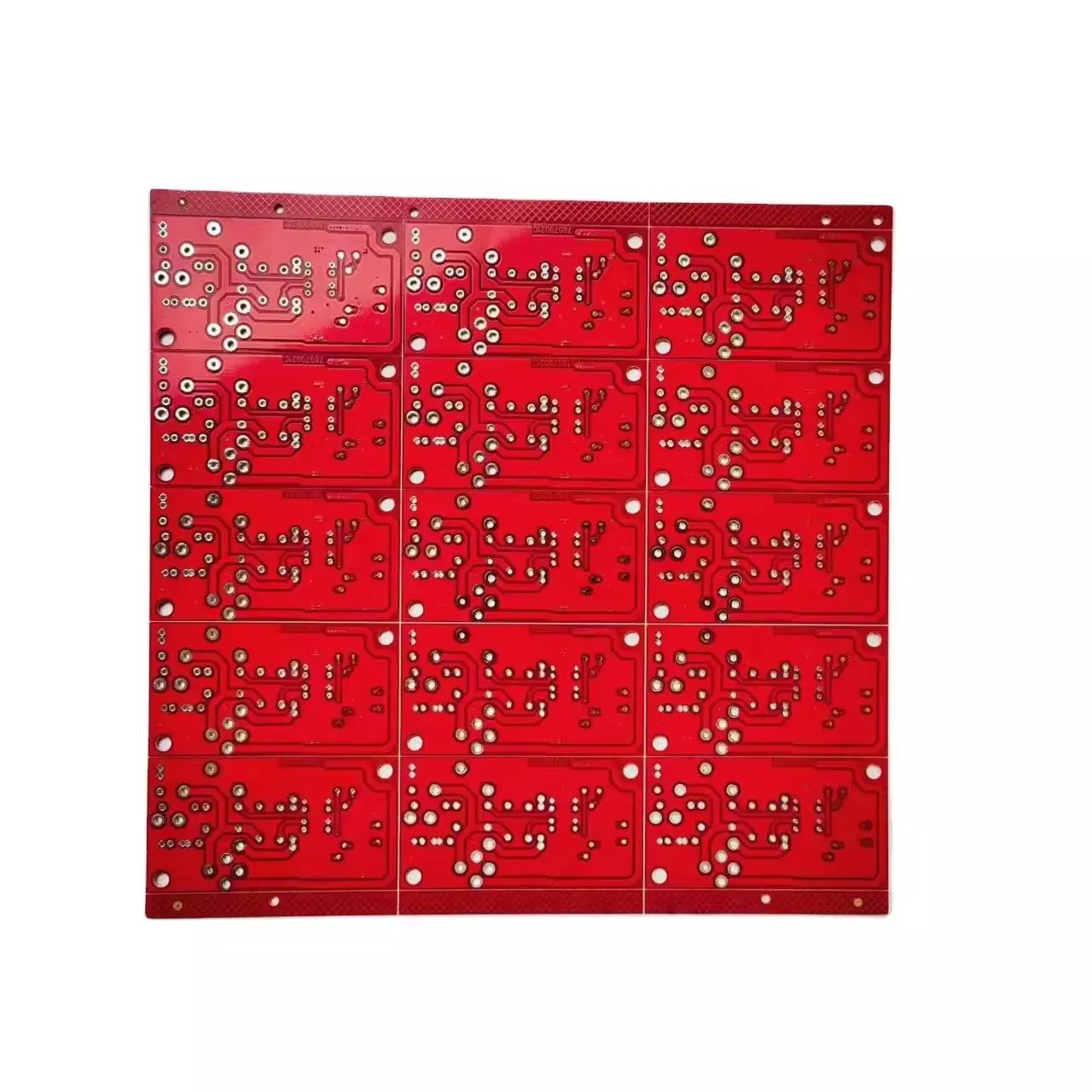

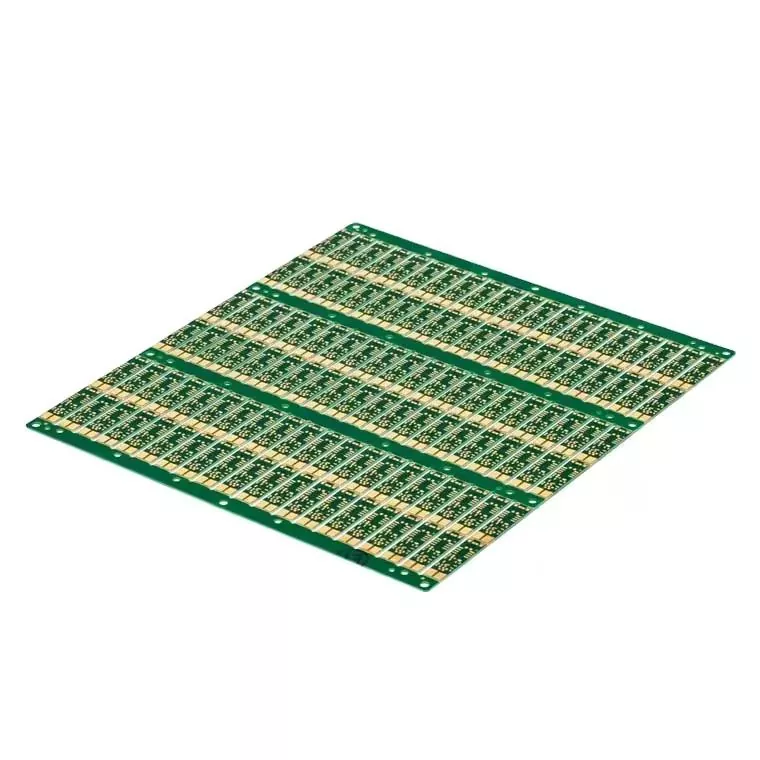

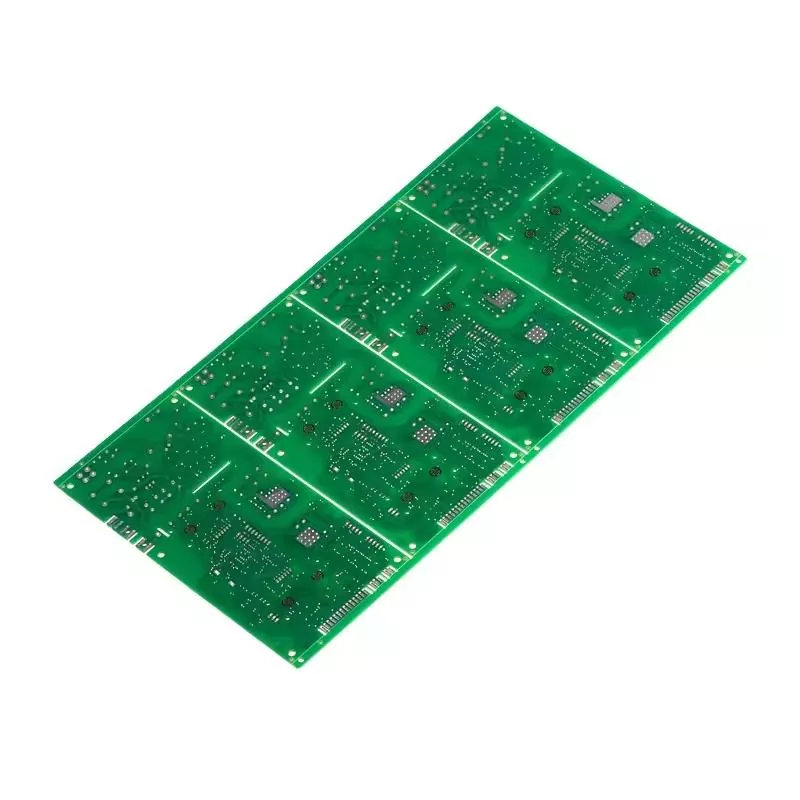

Hoshineo Lcd-Tech China Anti-Oxidation PCB Details

Packing & Delivery

Employ thickened plastic vacuum packaging for superior sealing strength and resistance to breakage. The exterior packaging utilizes a 3K-K laminated carton, further reinforced with foam padding for added protection.

FAQ

Q:Can you help with design?

A:Yes, we have a professional design team. If you have only one idea, we can help you implement the schematic design, the circuit diagram design, the Gerber file design. Build a professional team for you according to your needs.

Q:How do you ensure our long-term business relationship?

A:We are sincerely hoping to establish the good long-term business relationship with our esteemed clients, so we will do our best to guarantee our customers' benefit, stable quality and competitive prices are essential,and we are also provide our increasingly advanced technology for our clients to meet the increasing needs in the current markets

Q:PCB storage cycle?

A:The storage period of PCB is mainly distinguished by surface treatment.

HAL, LF-HAL, Immersion Gold or ENIG surface process: shelf life 1 year

OSP, Immersion Silver, Immersion Sn: shelf life 6 months

Storage conditions: temperature 20-28 ℃, humidity ≤80%, vacuum packaging