Electroless Nickel Immersion Gold PCB

Hoshineo Lcd-Tech is deeply engaged in the wholesale field of electronic components and display devices, Electroless Nickel Immersion Gold PCB, specializing in all kinds of instruments, socket meters, electric meters (including track meters), liquid crystal displays and electronic special equipment. We adhere to the core concept of providing customers with diversified and excellent quality products, and constantly pursue excellence, aiming to build a long-term and stable cooperation bridge with our customers and create a brilliant future.

Send Inquiry

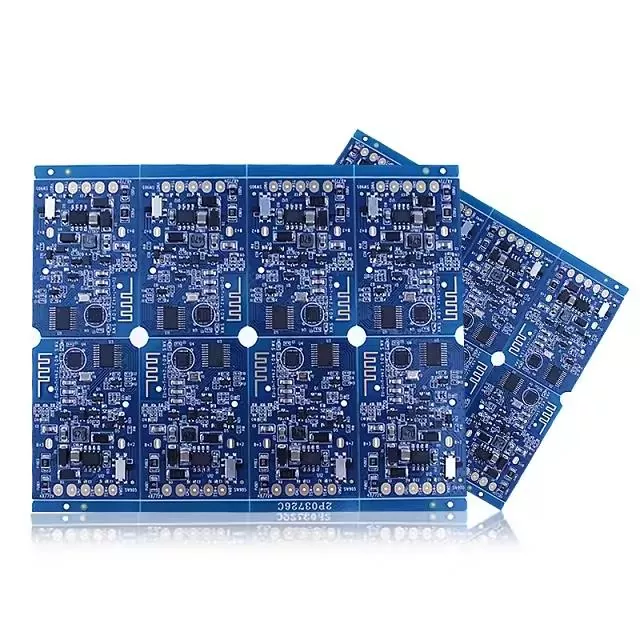

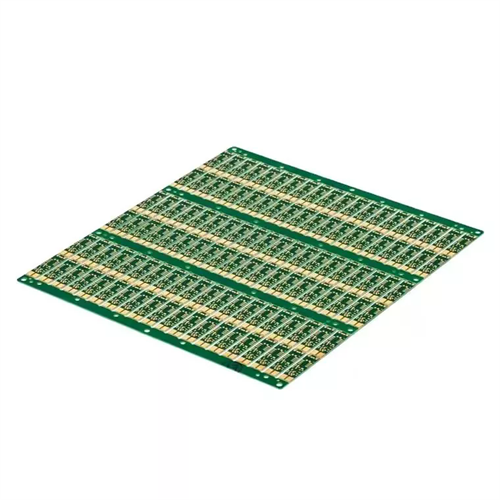

Electroless Nickel Immersion Gold PCB provided by Hoshineo Lcd-Tech is widely used in many fields. ENIG process is a surface treatment process of electroless nickel plating on PCB bare copper and then gold leaching. The treated PCB board has good contact conductivity and assembly and welding performance.

Hoshineo Lcd-Tech China Electroless Nickel Immersion Gold PCB Specification

|

item |

value |

|

Place of Origin |

zhejiang, China |

|

Base Material |

FR-4/ High TGFR-4/Arlon |

|

Copper Thickness |

1-5 oz |

|

Board Thickness |

1.0MM |

|

Min. Hole Size |

0.2MM |

|

Min. Line Width |

0.1mm/3MIL |

|

Min. Line Spacing |

0.1mm/3MIL |

|

Surface Finishing |

ENIG |

|

Board Size |

OEM PCB |

|

Application |

Electronics Device |

|

Type |

Mainboard PCB Assembly |

|

Style |

Consume Electronic PCBA |

|

Interface |

LVDS, EDP, RS232, UART, USB, PCIE, Audio, RJ45, HD, Mr. Speaker. |

|

Size |

14X10X2cm |

|

Weight |

1kg |

|

Certificate |

ISO ROHS for PCB PCBA assembly |

Hoshineo Lcd-Tech China Electroless Nickel Immersion Gold PCB Feature

Protect copper surface:

ENIG process through the formation of a layer of nickel phosphorus alloy layer and gold layer on the copper surface, effectively prevent copper oxidation and corrosion, protect the PCB copper line and pad.

High welding reliability:

The gold layer has good welding performance, so that the components can be solidly welded on the PCB, improving the reliability and stability of the welding points.

Meet the requirements of small-pitch components:

With the continuous miniaturization and integration of electronic products, the requirements for PCB surface smoothness are getting higher and higher. The ENIG process provides a high flatness surface to meet the welding needs of small-pitch components.

Extend PCB life:

The dual protection of nickel and gold layers enables Electroless Nickel Immersion Gold PCB to have a longer service life. Stable performance and reliability, even in harsh environments.

Hoshineo Lcd-Tech China Electroless Nickel Immersion Gold PCB Details

Packing & Delivery

Utilize vacuum packaging made from thickened plastic to ensure exceptional sealing strength and resilience against breakage. For enhanced external protection, the packaging employs a sturdy 3K-K laminated carton, which is further bolstered with foam padding for additional safeguard measures.

FAQ

Q:What is standard delivery term?

A:Delivery terms of EXW, FCA, FOB, DDU etc. are all available based on each quote.

Q:How long does it take for PCB quote?

A:Normally 12 hours to 48 hours as soon as receive internal engineer evaluate confirmation.

Q:Do you have any minimum order quantity (MOQ) requirement?

A:No, we do not have MOQ requirement, we can support your projects starting from prototypes to mass productions.