Printed Circuit Assembly

One of Chinese manufacturer of Printed Circuit Assembly, offering excellent quality at a competitive price, is Hoshineo Lcd-Tech. Feel free to get in touch.

Send Inquiry

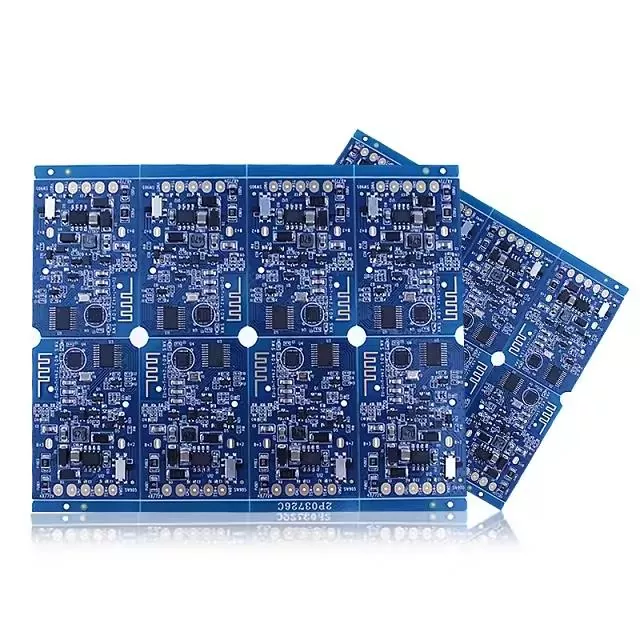

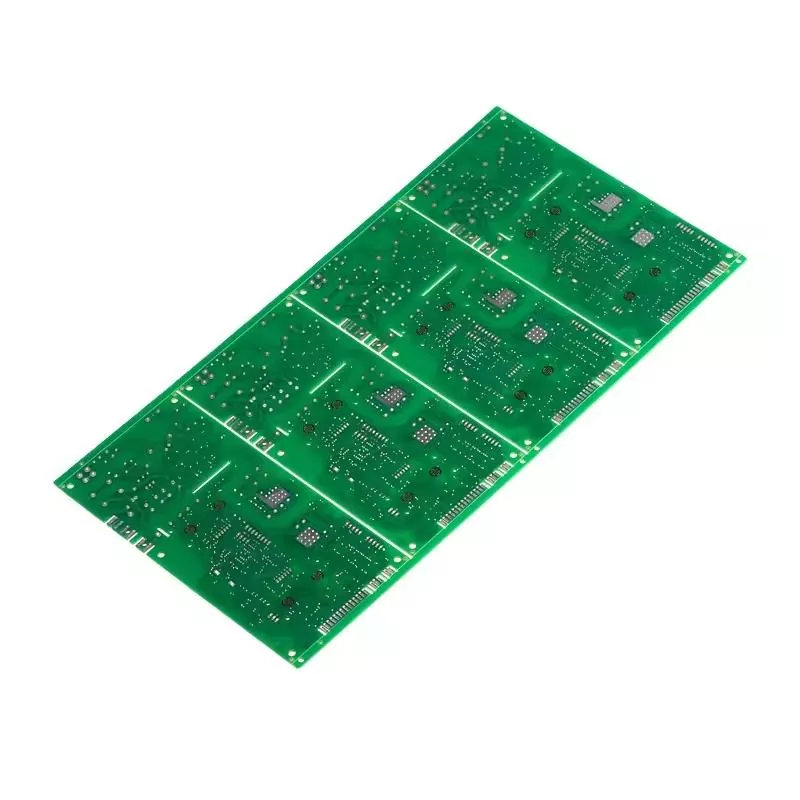

Our Printed Circuit Assembly process begins with a thorough consultation to understand your exact specifications and design needs. Our experienced team of designers use the latest software tools to transform your plans and to create a fully-functional prototype. Once the prototype is approved, we then use our state-of-the-art PCA production methods to ensure consistency and quality in every PCA we manufacture.

As a leading provider of high-quality Printed Circuit Assembly services, we use only superior-grade materials and adhere to strict quality control processes to ensure that your PCA designs meet all relevant industry standards and regulations. Additionally, we offer competitive pricing for our PCA services and work within your budget to deliver the best possible results.

Hoshineo Lcd-Tech Standard Black Solder Mask PCB Product function and specification

|

Item |

Specification |

|

|

1 |

Numbr of Layer |

1-18Layers |

|

2 |

Material |

FR-4,FR2.Taconic,Rogers, CEM-1 CEM-3,ceramic , crockery Metal-backed Laminate |

|

3 |

Surface Finish |

HASL(LF), Gold plating, Electroless nickel immersion gold, Immersion Tin, OSP(Entek) |

|

4 |

Finish Board Thickness |

0.2mm-6.00 mm(8mil-126mil) |

|

5 |

Copper Thickness |

1/2 oz min;12 oz max |

|

6 |

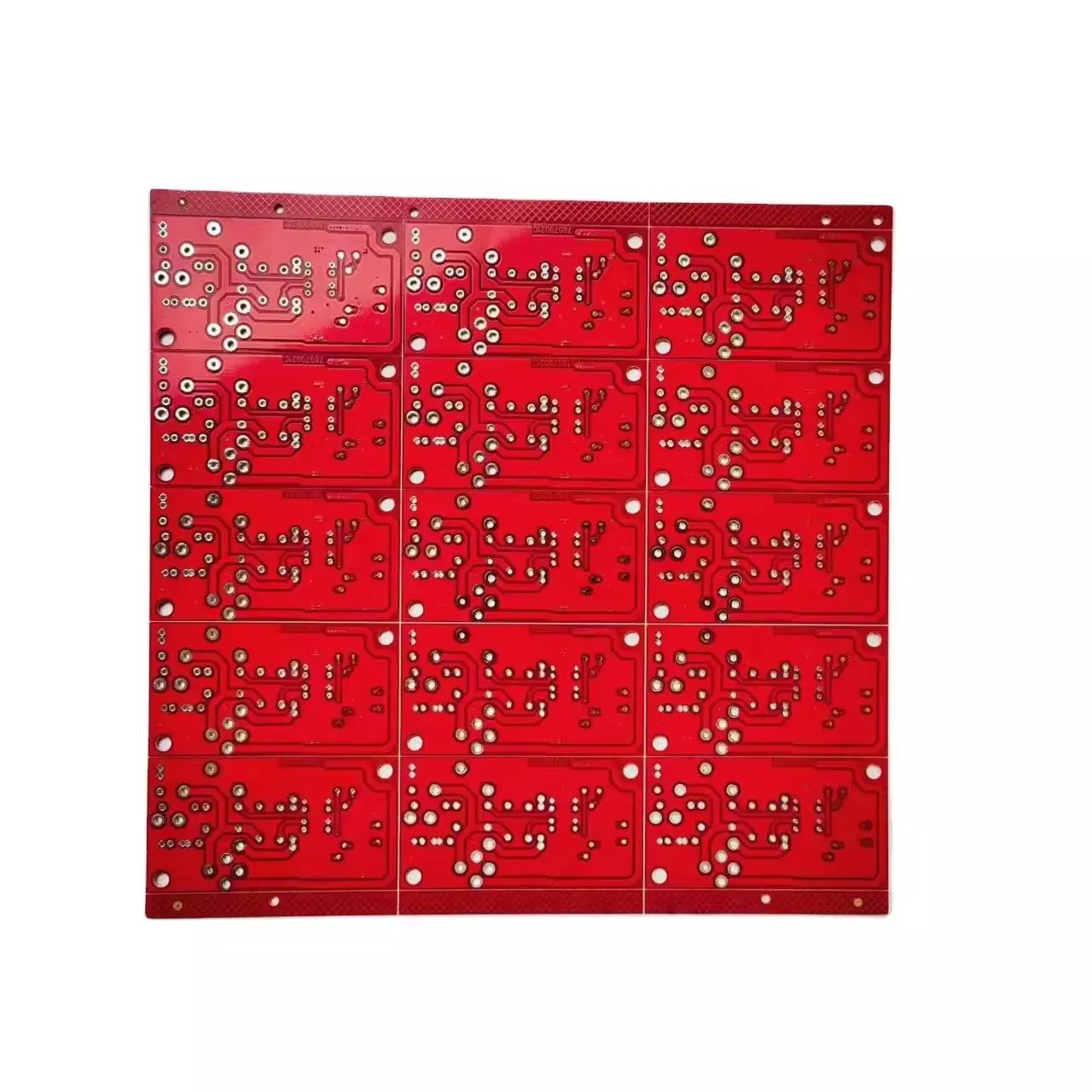

Solder Mask |

Green/Black/White/Red/Blue/Yellow |

|

7 |

Min.Trace Width & Line Spacing |

0.075mm/0.1mm(3mil/4mil) |

|

8 |

Min.Hole Diameter for CNC Driling |

0.1mm(4mil) |

|

9 |

Min.Hole Diameter for punching |

0.9mm(35mil) |

|

10 |

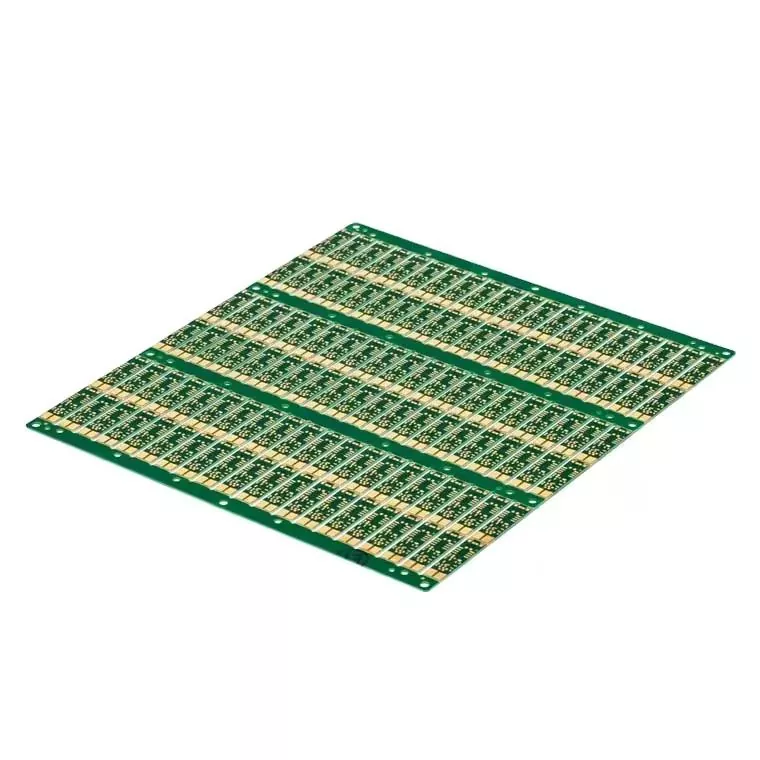

Biggest panel size |

610mm*508mm |

|

11 |

Hole Positon |

+/-0.075mm(3mil) CNC Driling |

|

12 |

Conductor Width(W) |

0.05mm(2mil)or; +/-20% of original artwork |

|

13 |

Hole Diameter(H) |

PTH L:+/-0.075mm(3mil); Non-PTH L:+/-0.05mm(2mil) |

|

14 |

Outline Tolerance |

0.125mm(5mil) CNC Routing; +/-0.15mm(6mil) by Punching |

|

15 |

Warp & Twist |

0.70% |

|

16 |

Insulation Resistance |

10Kohm-20Mohm |

|

17 |

Conductivity |

<50ohm |

|

18 |

Test Voltage |

10-300V |

|

19 |

Panel Size |

110×100mm(min);660×600mm(max) |

|

20 |

Layer-layer misregistration |

4 layers:0.15mm(6mil)max; 6 layers:0.25mm(10mil)max |

|

21 |

Min.spacing between hole edge to circuity pqttern of an inner layer |

0.25mm(10mil) |

|

22 |

Min.spacing between board oulineto circuitry pattern of an inner layer |

0.25mm(10mil) |

|

23 |

Board thickness tolerance |

4 layers:+/-0.13mm(5mil); 6 layers:+/-0.15mm(6mil) |

|

24 |

Impedance Control |

+/-10% |

|

25 |

Different Impendance |

+-/10% |

Hoshineo Lcd-Tech Standard Black Solder Mask PCBUsage Scenario

High-end electronics: In high-end consumer electronics products, such as smartphones, tablets, high-end audio, etc., Standard Black Solder Mask PCB can not only provide excellent circuit protection, but also improve the overall texture and beauty of the product, to meet consumers' high requirements for product appearance.

Medical equipment: Medical equipment usually has high requirements for the appearance and identification of products, and the unique black appearance of Standard Black Solder Mask PCB helps to distinguish and identify equipment, while meeting the strict requirements of medical equipment for circuit stability and safety.

High temperature environment: TheStandard Black Solder Mask PCB can withstand the high temperature during the high temperature welding process, so it has a wide range of applications in electronic products that require high temperature welding or work in a high temperature environment, such as automotive electronics, industrial control equipment, etc.

Moisture-proof and anti-corrosion requirements: The black solder block layer has good moisture-proof and anti-corrosion properties, and is suitable for electronic products that need to work in a humid or corrosive environment for a long time, such as Marine detection equipment, chemical equipment control board and so on.

Optical scanning and identification: In some cases where optical scanning or identification of barcodes or marks on the circuit board is required, Standard Black Solder Mask PCB can provide a clear and stable background, improving the accuracy and reliability of optical scanning.

Hoshineo Lcd-Tech Standard Black Solder Mask PCB Details

Packaging & shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q: What’s the lead time?

A: After you place a order,the production handling time is about 20-25 days depends on your quantity.

Q: How do you ship the goods?

A: We ship samples by via fast express, for bulk orders will be shipped by sea or train.

Q: Can you change configuration for me?

A: Yes, we can change configuration based on customers’ request